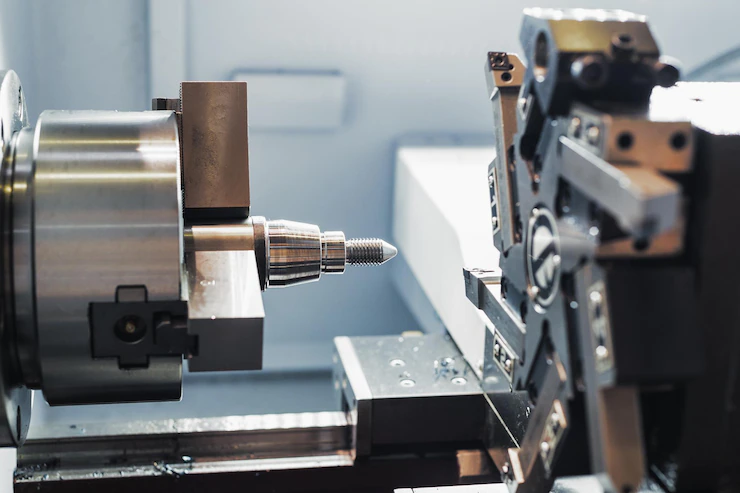

CNC Milling machine give backing to the assembling persistence. The Milling machines can perform every Milling activity like stuff Milling, string Milling, rakish Milling, etc.

What Is A CNC Milling Machine?

The CNC Milling machine are utilized to eliminate pith from the workpiece to get the requested shape with the assistance of a spinning blade called a Milling blade. This is used on level, harsh, and unpredictable shells, and it’s finished by placing the workpiece inverse to the pivoting Milling blade.

The CNC Precision Machining Components the Milling engine through computerized signals for handling. The workpiece is moved in the XY plane. Furthermore, the Z hub is the apparatus shaft., which is moderately powerful for small or mass items. The Milling machine can fix the workpiece, and the borer, by and large, makes 3D or 2D workpieces, which can straightforwardly shop the workpieces in bright shapes comparable to planes, shells, notches, and pinion wheels. The benefit of Milling is the high pith trashing rate while pondering workpieces with rotational roundabout blades and the capacity to stop in a genuinely time. Because of the various shapes and mechanical activity styles of the Milling blades, the CNC Turning Machine can perform bright Milling errands, including planes.

Milling, face Milling, groove Milling, gear Milling, cam milling, etc., can utilize the shaping Milling blade to shop complex outlines all at once. Complete with the ordering head can shop the winding section.

What Is the hall of A CNC Milling Machine?

The variables of the CNC Milling machine incorporate Column and Base, Knee, Saddle and Swivel Table, Power Feed Medium, Table, Spindle, Over Arm/Overhanging Arm, Arbor Support, and Ram. Figure out what CNC Milling machine passage and capabilities are accessible underneath.

Segment and base

Segment and base give upholds for the other passageway of a CNC Milling machine. An oil painting power and siphon are in the section to smooth the axle. The area lies on the base, and it has a coolant force and a siphon to give coolant in machining tasks.

Knee

The outfitting medium is encased inside a knee. The knee is secured to the section by dovetail ways. It’s upheld and adjusted by an opposite situating screw, a hoisting screw. The utilization of the hoisting screw is to adapt the knee all over by raising or bringing down the switch with the assistance of a hand or power feed.

Seat and Swivel Table

The contamination is on the knee and supports the table. Saddle slides on vertical dovetail on the knee and dovetail are resemblant to the pivot of the shaft( in vertical Milling m/c). Turn table is appended to the pollute that twirled( spun) on a level plane in the two headings.

Power Feed Medium

The power feed medium is in the knee. The power feed medium is utilized to control longitudinal( left and right), cross over( in and out), and opposite( finished and down) takes care of. The feed choice switch is shown on the feed determination plates for the requested rate from the machine. For some general knee and section CNC Milling machine, the spread is achieved by turning the speed determination handle till the required pace of meal is displayed on the feed dial. Almost in each Milling device, a fast fire cut switch is utilized when an impermanent speed up the longitudinal, cross over, or opposite takes care is required. This switch is used when the driver is adjusting or arranging the work.

Table

A table is a blockish projecting introduced on the highest point of a contaminate. The table is utilized to hold the work or for work holding inclination. There are a few T-spots to have endlessly work holding predisposition( wiles and establishments). It very well may be operated manually or by power. For moving the table the hard way, it draws in and turns the longitudinal hand curl. For moving it by force, it draws in longitudinal heading and takes care of the control switch.

Axle

The shaft is utilized to hold and drive the cut instruments of a CNC Milling machine. It’s mounted on the comportments and has the help of the segment. An electric engine drives the axle employing stuff trains on the element. The axle face lies close to the table and has an inside tighten machined. Two keys at the front-facing front give a positive drive for the blade holder or vault.

Over Arm/Overhanging Arm

Overarm is an upward beam, and it’s on the top essence of the section. It could be a solitary projecting and slides on the dovetail way on the segment’s ultimate substance.

Arbor Support

Arbor support is projecting with an orientation that upholds the exterior finish of a vault. It additionally assists with adjusting the outdoor finish of the arbour with the axle. Arbor support forestalls the Milling of the outdoor finish of locker in cutting tasks. By and large, there are two sorts of vault upholds utilized in the CNC Milling machine. The first has little outskirts bearing opening of a most extreme fringe of 1 inch. The substitute bone

has enormous outskirts bearing a gap of over to 23/4 inch.

Slam

The slam is an overhanging arm in an opposite CNC Milling machine. The one finish of the hit is mounted on the highest point of the section, and the Milling head is connected to another.

Embellishments for CNC Milling Machine

Customary CNC Milling machine embellishments incorporate opposite Milling connections, turn connections, fast Milling connections, opening links, widespread isolating heads( ordering heads), backhanded Milling connections, rack Milling connections, indecencies, and screens.