Silicone has both domestic and industrial applications. It is used in several industries, including transportation, construction, and health care. In building and construction, silicone is popular because of its durability and resistance to weather, moisture, and sunlight. It works in adhesives and sealants for marine vessels. The commercial application of silicone is more varied than you would think. We look at the uses and benefits of silicon in industrial applications.

Uses and benefits

Silicone-based products comprise a versatile array of applications in the manufacturing industry. It is common in food manufacturing and medicine, where human contact is expected. Due to the wide range of forms, silicone has extensive industrial applications.

The compound is a chemically stable product with less volatility than natural rubber. It’s also easily manipulated and has high-temperature stability and age resistance.

Silicone usually operates with other materials to ensure that purify, soften, adhere, condition, and protect a product. For example, silicon-based materials improve appearance, transfer energy, and help reconstruction.

If an application requires a product to adhere to another, silicone enables bonding between the materials. On the other hand, you can tailor silicone to inhibit adhesion and keep each layer separate if the coating and adhesive layer need to remain independent.

1. Silicone Release Liners

A siliconized release liner allows the release of a sticky element and can prevent it from permanently attaching to the liner. It is used in various products and applications, including bandages and shipping envelopes.

Most release liners comprise several layers, with the top layer being silicone because of its anti-stick properties. They are used in manufacturing self-adhesive labels or adhesive bandages. Silicon natural properties allow the release liners to hold adhesives while making removal quick and easy. It works as a release liner for self-adhesive labels.

Silicone is also used in manufacturing specific labels, such as show labels, bag labels, or footwear labels. The self-adhesive labels are attached to the release liner and can later be peeled off when applied over a surface.

2. Siliconized Paper

This is a type of paper over which a silicone layer has been applied. You can apply the silicone to one or both sides of the paper. The thickness of silicone applied over a paper varies depending on the purpose for which the paper will be used.

Adding silicon to paper enhances flexibility and resistance to moisture, heat, cold, and ultraviolet radiation. It has unique properties that prevent sticky elements like moisture or glue from getting attached.

Silicone paper is used to pack food products and as a holder for self-adhesive labels. It protects products, machines, or equipment from external agents like moisture or grease.

3. Silicon Rubber

Silicone rubber is an effective ingredient in computers and electronics, automobiles, textiles, health products, construction, and household products. Its exceptional insulation properties allow it to work in the electrical industry to coat and protect wires. For instance, silicone rubber provides proper insulation for technical wiring.

Application of silicone-based products

- Personal care products

Silicon is used in personal care products to reduce the white residue and the tacky feel of antiperspirants in deodorants. These products obtain a smooth feel from silicon.

It’s long-lasting and helps retain the color and luster associated with cosmetics, shampoos, and conditioners. Silicone’s wetting and spreading qualities provide smooth and even application of cosmetics, lotion, sunscreen, and cleansers.

- Energy

Silicone has properties that improve the efficiency, durability, and performance of solar panels and photovoltaic devices. Its ability to stand the sun for years makes it an ideal material for solar panel application.

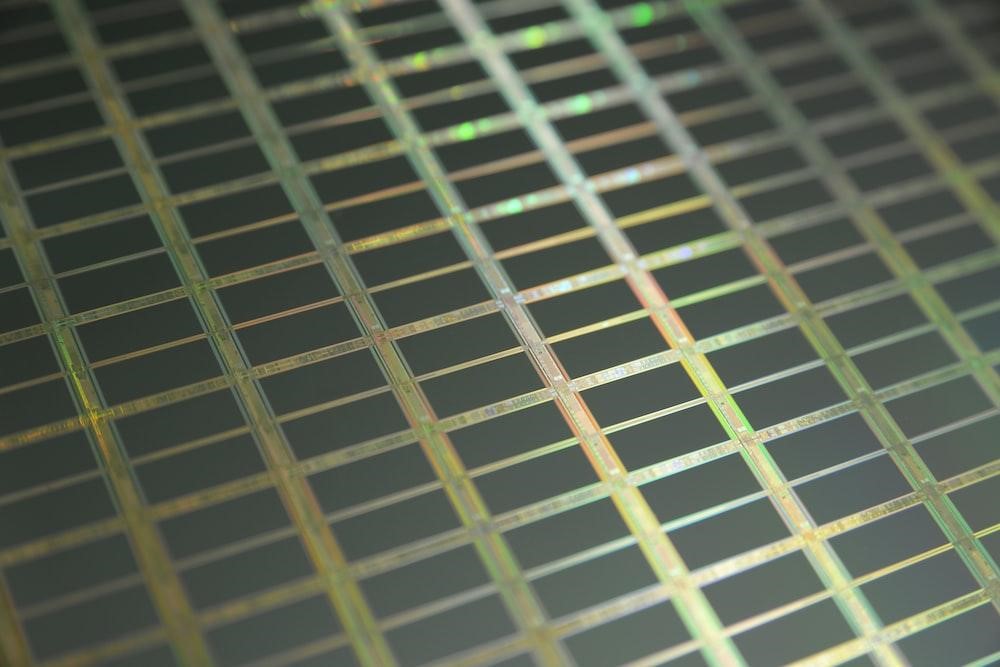

- Computer and Electronics

Sturdy and durable silicone makes keypads, keyboards, and copier rollers. They all depend on silicon-based materials for protection and insulation. Also, it is used on many computer components, mobile electronics, and home entertainment equipment. Silicones play a role in enabling LED lighting technology. The high thermal stability and excellent dielectric properties allow for use in various electrical transmission applications.

- Aviation

The silicone’s ability to stand stress and temperature extremes allow them to be used in the aviation industry. The silicone adhesive and sealant are used to seal and protect doors, windows, wings, fuel tanks, hydraulic switches, overhead bins, wing edges, landing gear electrical devices, vent ducts, engine gaskets, electrical wires, and black boxes. The silicone’s malleable nature allows it to be molded and bonded in different ways to seal and protect aircraft parts.

Silicone offers flexible solutions in dealing with incredible temperatures and extreme pressures that aviation design engineers face. The silicone engineers have manufactured and supplied unique products for the aerospace sector. They maintain the highest safety standards and ensure the silicon materials conform to the industry safety specifications in applications where passengers’ safety is critical.

- Construction and architecture

Silicones are used in the construction and renovation of commercial and residential buildings. They enable glass-walled skyscrapers and energy-efficient architecture. You can use silicone sealant and caulks at home to reduce energy usage and prevent damage from moisture and bacteria buildup. It’s used in floor joints, sinks, tubs, and showers to prevent water leakage.

- Kitchenware

The flexibility and non-stick surface of silicone bakeware and cookware are easy to clean and do not impact the flavor or odor of food. For example, you can take cake pans, muffin molds, and baking mats from the freezer to the oven, microwave, or dishwasher without affecting food taste or quality.

- Paints and coatings

Silicone-enhances paint keeps the exterior coatings of houses or bridges flexible so they can withstand freeze-and-thaw cycles without cracking. The coatings on the highway and road surfaces are less likely to rust when exposed to salt spray and acid rain.

- Sporting goods and apparel

Silicone has properties that seal water from diving masks and goggles. It can alter the texture and make a fabric material waterproof. They enable new techniques to design lightweight, durable, water-repellent, and high-performing sportswear while allowing the fabric to maintain breathability.

Bottom line

The versatility of silicone stems from its performance and protective qualities. It’s used across some of the most strenuous and yet some of the most sensitive applications. For example, silicon adds industrial strength to courting sealants and joints in bridges, highways, skyscrapers, and ocean vessels. When used in personal and health care products, silicone makes lotions, topical medications, and skin adhesives easy to apply and less irritating.